PIPA LAS BAJA KARBON ERW PIPA BAJA LAS SSAW PIPA BAJA LAS LSAW PIPA BAJA LAS

Katrangan

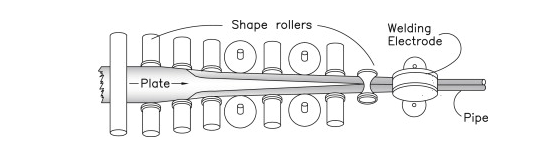

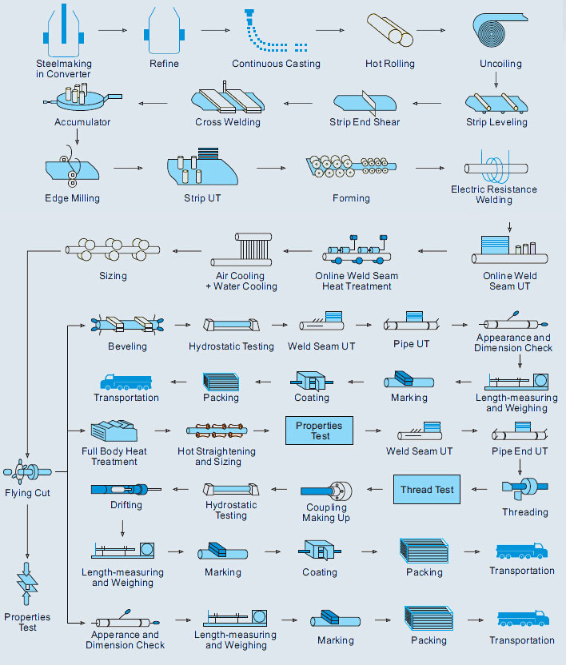

Butt-gandheng pipe iki kawangun dening dipakani piring baja panas liwat wangun sing bakal muter menyang wangun bunder kothong.Meksa rong ujung piring bebarengan bakal ngasilake gabungan utawa jahitan sing digabung.Gambar 2.2 nuduhake piring baja nalika miwiti proses mbentuk pipa sing dilas

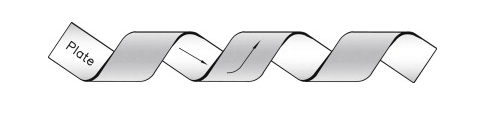

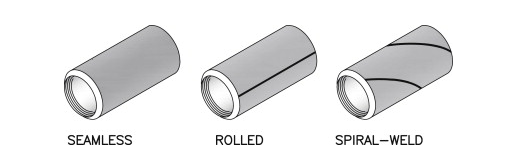

Paling ora umum saka telung cara yaiku pipa spiral-welded.Pipa sing dilas spiral dibentuk kanthi cara nggulungake potongan logam dadi bentuk spiral, padha karo kutub tukang cukur, banjur las ing ngendi pinggiran gabung siji liyane kanggo mbentuk jahitan.Pipa jinis iki diwatesi kanggo sistem pipa kanthi tekanan rendah amarga tembok sing tipis.Gambar 2.3 nuduhake pipa spiral-welded kaya sing katon sadurunge welding.

Saben telung cara kanggo ngasilake pipa nduweni kaluwihan lan kekurangan.Pipa sing dilas butt, umpamane, dibentuk saka piring sing digulung kanthi ketebalan tembok sing luwih seragam lan bisa dipriksa kanggo cacat sadurunge dibentuk lan dilas.Cara manufaktur iki utamané migunani nalika tembok tipis lan dawa dawa dibutuhake.Nanging, amarga jahitan sing dilas, mesthi ana kemungkinan cacat sing bisa lolos saka pirang-pirang pemeriksaan kontrol kualitas sing ditindakake sajrone proses manufaktur.

Akibaté, American National Standards Institute (ANSI) ngembangake pedoman sing ketat kanggo nggawe pipa.Kode Pipa Tekanan B31 ditulis kanggo ngatur produksi pipa.Utamane, kode B31.1.0 nemtokake faktor kekuatan 85% kanggo pipa sing digulung, 60% kanggo pipa sing dilas spiral, lan efisiensi 100% kanggo pipa sing mulus.

Umume, kekandelan tembok sing luwih akeh diprodhuksi kanthi cara sing mulus.Nanging, kanggo akeh panggunaan pipa tekanan rendah, metode las terus-terusan paling ekonomis.Pipa mulus diprodhuksi ing dawa acak tunggal lan kaping pindho.Dawane acak tunggal beda-beda saka 16′-0″ nganti 20′-0″.Pipa 2″lan ngisor ditemokake kanthi acak ganda kanthi ukuran saka 35′-0″ nganti 40′-0″.

Spesifikasi

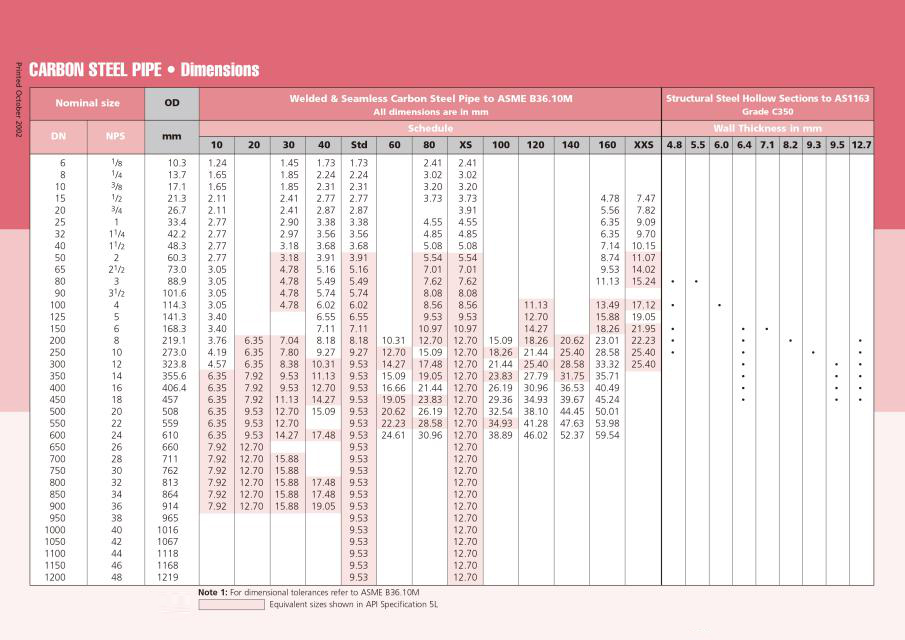

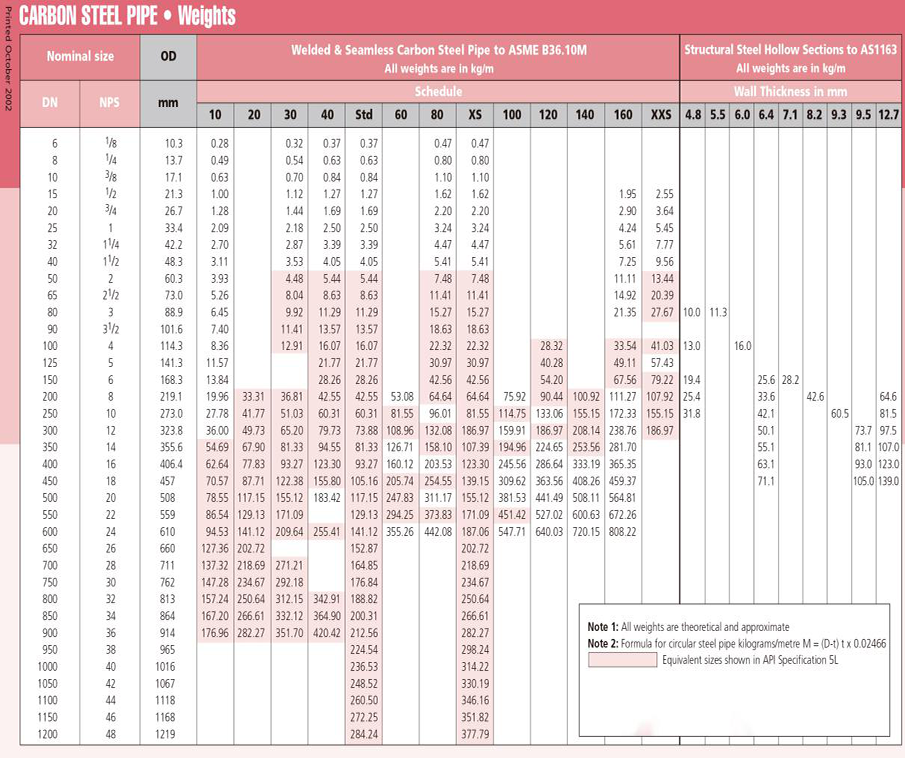

Ukuran lan bobot pipa baja karbon sing dilas & mulus

| Pipa Karbon, Fitting lan Flanges | |

| Wangun | Welded (RW) lan Seamless |

| Aplikasi | Fluida, Struktural |

| Ukuran Range | DN15 - DN600 |

| biji | 250, 350 |

| Ketebalan Tembok | Std Wt, XS |

| Tipe Fitting | Las butt, Screwed & socket, Flanges, Fitting ireng lan Galvanis kanggo EN10241 (BS 1740) |

| Bentuk Fitting | Siku, Tee, Reducer, Caps, Stub ends, Flanges (ANSI, Tabel E, D lan H) |

| Ngolah | Cut-kanggo-dawa, |

Standar

Lembar spesifikasi pipa las lurus

| Spesifikasi (mm) | OD (diameter njaba) | kekandelan tembok | bobot |

| 1/2 inchi | 21.25 | 2.75 | 1.26 |

| 3/4 inchi | 26.75 | 2.75 | 1.63 |

| 1 inchi | 33.3 | 3.25 | 2.42 |

| 11/4 inchi | 42.25 | 3.25 | 3.13 |

| 11/2 inchi | 48 | 3.5 | 3.84 |

| 2 inchi | 60 | 3.5 | 4.88 |

| 21/2 inchi | 75.5 | 3.75 | 6.64 |

| 3 inchi | 88.5 | 4.0 | 8.34 |

| 4 inch | 114 | 4.0 | 10.85 |

| 5 inch | 140 | 4.5 | 15.04 |

| 6 inch | 165 | 4.5 | 17.81 |

| 8 inch | 219 | 6 | 31.52 |

Tabel spesifikasi pipa las spiral lipat

| spesifikasi | kekandelan tembok | Bobot saben meter | Nilai tekanan banyu standar nasional | Nilai tekanan banyu nominal | spesifikasi | kekandelan tembok | Bobot saben mete | Nilai tekanan banyu standar nasional | Nilai tekanan banyu nominal |

| 219 | 6 | 32.02 | 9.7 | 7.7 | 720 | 6 | 106.15 | 3 | 2.3 |

| 7 | 37.1 | 11.3 | 9 | 7 | 123.59 | 3.5 | 2.7 | ||

| 8 | 42.13 | 12.9 | 10.3 | 8 | 140.97 | 4 | 3.1 | ||

| 273 | 6 | 40.01 | 7.7 | 6.2 | 9 | 158.31 | 4.5 | 3.5 | |

| 7 | 46.42 | 9 | 7.2 | 10 | 175.6 | 5 | 3.9 | ||

| 8 | 52.78 | 10.3 | 8.3 | 12 | 210.02 | 6 | 4.7 | ||

| 325 | 6 | 47.7 | 6.5 | 5.2 | 820 | 7 | 140.85 | 3.1 | 2.4 |

| 7 | 55.4 | 7.6 | 6.1 | 8 | 160.7 | 3.5 | 2.7 | ||

| 8 | 63.04 | 8.7 | 6.9 | 9 | 180.5 | 4 | 3.1 | ||

| 377 | 6 | 55.4 | 5.7 | 4.5 | 10 | 200.26 | 4.4 | 3.4 | |

| 7 | 64.37 | 6.7 | 5.2 | 11 | 219.96 | 4.8 | 3.8 | ||

| 8 | 73.3 | 7.6 | 6 | 12 | 239.62 | 5.3 | 4.1 | ||

| 9 | 82.18 | 8.6 | 6.8 | 920 | 8 | 180.43 | 3.1 | 2.5 | |

| 10 | 91.01 | - | 7.5 | 9 | 202.7 | 3.5 | 2.8 | ||

| 426 | 6 | 62.25 | 5.1 | 4 | 10 | 224.92 | 3.9 | 3.1 | |

| 7 | 72.83 | 5.9 | 4.6 | 11 | 247.22 | 4.3 | 3.4 | ||

| 8 | 82.97 | 6.8 | 5.3 | 12 | 269.21 | 4.7 | 3.7 | ||

| 9 | 93.05 | 7.6 | 6 | 1020 | 8 | 200.16 | 2.8 | 2.2 | |

| 10 | 103.09 | 8.5 | 6.7 | 9 | 224.89 | 3.2 | 2.5 | ||

| 478 | 6 | 70.34 | 4.5 | 3.5 | 10 | 249.58 | 3.5 | 2.8 | |

| 7 | 81.81 | 5.3 | 4.1 | 11 | 274.22 | 3.9 | 3 | ||

| 8 | 93.23 | 6 | 4.7 | 12 | 298.81 | 4.2 | 3.3 | ||

| 9 | 104.6 | 6.8 | 5.3 | 1220 | 8 | 239.62 | - | 1.8 | |

| 10 | 115.92 | 7.5 | 5.9 | 10 | 298.9 | 3 | 2.3 | ||

| 529 | 6 | 77.89 | 4.1 | 3.2 | 11 | 328.47 | 3.2 | 2.5 | |

| 7 | 90.61 | 4.8 | 3.7 | 12 | 357.99 | 3.5 | 2.8 | ||

| 8 | 103.29 | 5.4 | 4.3 | 13 | 387.46 | 3.8 | 3 | ||

| 9 | 115.92 | 6.1 | 4.8 | 1420 | 10 | 348.23 | 2.8 | 2 | |

| 10 | 128.49 | 6.8 | 5.3 | 14 | 417.18 | 3.2 | 2.4 | ||

| 630 | 6 | 92.83 | 3.4 | 2.6 | 1620 | 12 | 476.37 | 2.9 | 2.1 |

| 7 | 108.05 | 4 | 3.1 | 14 | 554.99 | 3.2 | 2.4 | ||

| 8 | 123.22 | 4.6 | 3.6 | 1820 | 14 | 627.04 | 3.3 | 2.2 | |

| 9 | 138.33 | 5.1 | 4 | 2020 | 14 | 693.09 | - | 2 | |

| 10 | 153.4 | 5.7 | 4.5 | 2220 | 14 | 762.15 | - | 1.8 |

Painting & Coating

Enteng lenga, Hot dip galvanis, Electrogalvanis, Ireng, Bare, Lapisan Varnish / Minyak Anti karat,Lapisan protèktif

Packing & Loading