ASTM A53 Carbon Steel Seamless Pipe Carbon Steel Seamless tube Pipa Baja Seamless

Pambuka

ASTM A53 Grade B minangka bahan miturut standar pipa baja Amerika, API 5L Gr.B uga minangka bahan standar Amerika, A53 GR.B ERW nuduhake pipa baja las listrik saka A53 GR.B;API 5L GR.B Welded nuduhake materi Welded pipe baja API 5L GR.B.

Pipa A53 teka ing telung jinis (F, E, S) lan rong gelar (A, B).

A53 Tipe F diprodhuksi nganggo weld butt furnace utawa bisa uga duwe weld terus-terusan (mung Kelas A)

A53 Tipe E nduweni las tahan listrik (Kelas A lan B)

A53 Tipe S minangka pipa sing mulus lan ditemokake ing Kelas A lan B)

Pipa ASTM A53 (uga diarani pipa ASME SA53) dirancang kanggo aplikasi mekanik lan tekanan, lan uga cocog kanggo panggunaan umum ing saluran uap, banyu, gas lan udara.Iku cocok kanggo welding lan mbentuk operasi kalebu nduwurke tumpukan, mlengkung lan flanging, miturut syarat tartamtu.

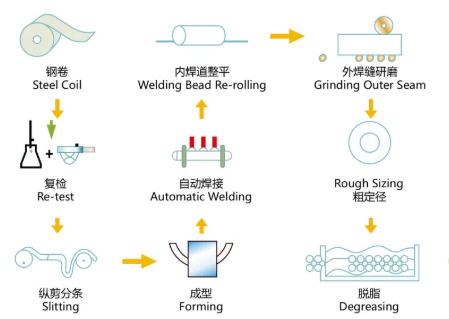

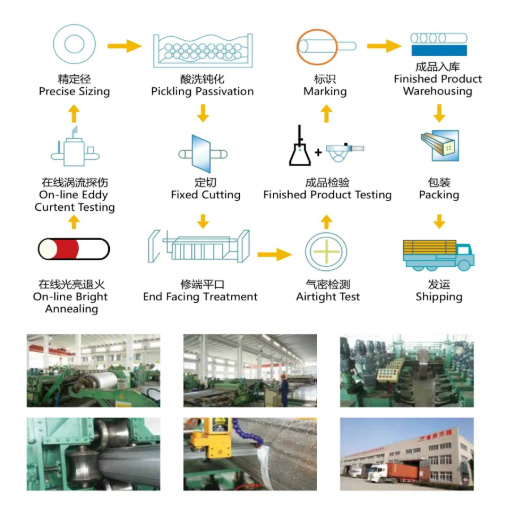

Proses Produksi

Data Teknis

| sasmita | C, maks | Mn, maks | P, maks | S, maks | Cu*, maks | Ni*, maks | Cr*, maks | Mo*, maks | V*, maks | |

| Tipe S (Mulus) | A | 0.25 | 0.95 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

| B | 0.3 | 1.2 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 | |

| Tipe E (Electric-resistance Welded) | A | 0.25 | 0.95 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

| B | 0.3 | 1.2 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 | |

| Tipe F (Furnace-welded) | A | 0.3 | 1.2 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

* Gunggung komposisi kanggo limang unsur kasebut ora ngluwihi 1,00%

Deskripsi Produk

Deskripsi Pipa Seamless Carbon Steel

| Jeneng produk | Pipa baja karbon mulus | |

| Ukuran | OD | 12.7mm-710mm |

| kekandelan | 3mm-45mm | |

| dawa | SRL, DRL, 5.8M, 11.8M | |

| Bahan Baja | ASTM A53/A106, API 5L, EN10216, DN162ASTM A179 A192 A210 | |

| Kelas Baja | Kelas A, Kelas B, Kelas C, X42, X52.S235JRH, S355, P265 etc. | |

| Proses | Hot mbalek / expansion panas / kadhemen digambar / kadhemen mbalek | |

| Panganggone | Layanan suhu dhuwur | |

| lumahing | Bared Black Painting, Galvanis, Coating | |

| Proktor | Tutup plastik | |

| Paket | Paket, Bulk | |

| Inspeksi | Kanthi Tes Hidraulik, Tes Ultrasonik utawa Tes X-ray | |

| Sertifikat | ISO9001;2000 | |

| Tanggal Pangiriman | Kurang saka 15/20/25/30/40/50/60 Dina Miturut Jumlah | |

| Pembayaran: | L / C utawa T / T | |

A.Komposisi kimia ing% Kanggo API 5L PSL1

| JENIS | Kelas baja | C . | Si | Mn. | P | S |

| API 5L PSL1 | B | ≤0,28 | - | ≤1.20 | ≤0.03 | ≤0.03 |

| API 5L PSL1 | X42 | ≤0,28 | - | ≤1.3 | ≤0.03 | ≤0.03 |

| API 5L PSL1 | X52 | ≤0,28 | - | ≤1.4 | ≤0.03 | ≤0.03 |

| API 5L PSL1 | X56 | ≤0,28 | - | ≤1.4 | ≤0.03 | ≤0.03 |

| API 5L PSL1 | X60 | ≤0,28 | - | ≤1.4 | ≤0.03 | ≤0.03 |

| API 5L PSL1 | X65 | ≤0,28 | - | ≤1.4 | ≤0.03 | ≤0.03 |

| API 5L PSL1 | X70 | ≤0,28 | - | ≤1.4 | ≤0.03 | ≤0.03 |

B.Mechanical Properties kanggo API 5L PSL1

| JENIS | kelas | Kekuwatan tensile (Mpa) | kekuatan ngasilaken (Mpa) | Elongation |

| API 5L PSL1 | B | ≥415 | ≥245 | Miturut API 5L |

| API 5L PSL1 | X42 | ≥415 | ≥290 | Miturut API 5L |

| API 5L PSL1 | X52 | ≥460 | ≥360 | Miturut API 5L |

| API 5L PSL1 | X56 | ≥490 | ≥390 | Miturut API 5L |

| API 5L PSL1 | X60 | ≥520 | ≥415 | Miturut API 5L |

| API 5L PSL1 | X65 | ≥535 | ≥450 | Miturut API 5L |

| API 5L PSL1 | X70 | ≥565 | ≥483 | Miturut API 5L |

C.Komposisi kimia ing% Kanggo API 5L PSL2

| tingkat | Kelas baja | C . | Si | Mn. | P | S |

| PSL2 | B | ≤0,24 | - | ≤1.20 | ≤0.03 | ≤0.03 |

| PSL2 | X42 | ≤0,24 | - | ≤1.3 | ≤0.03 | ≤0.03 |

| PSL2 | X52 | ≤0,24 | - | ≤1.4 | ≤0.03 | ≤0.03 |

| PSL2 | X56 | ≤0,24 | - | ≤1.4 | ≤0.03 | ≤0.03 |

| PSL2 | X60 | ≤0,24 | - | ≤1.4 | ≤0.03 | ≤0.03 |

| PSL2 | X65 | ≤0,24 | - | ≤1.4 | ≤0.03 | ≤0.03 |

| PSL2 | X70 | ≤0,24 | - | ≤1.4 | ≤0.03 | ≤0.03 |

D.Sifat Mekanik Kanggo API 5L PSL2

| tingkat | kelas | Kekuwatan tensile (Mpa) | kekuatan ngasilaken (Mpa) | Elongation |

| PSL2 | B | 415-760 | 245-450 | Miturut API 5L |

| PSL2 | X42 | 415-760 | 290-495 | Miturut API 5L |

| PSL2 | X52 | 460-760 | 360-530 | Miturut API 5L |

| PSL2 | X56 | 490-760 | 390-545 | Miturut API 5L |

| PSL2 | X60 | 520-760 | 415-565 | Miturut API 5L |

| PSL2 | X65 | 535-760 | 450-600 | Miturut API 5L |

| PSL2 | X70 | 565-758 | 483-621 | Miturut API 5L |

Transportasi

Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL utawa LCL utawa Bulk)